1.4112 SEISMOS® – X90CrMoV18

Description

Grade 1.4112 is a very high hardness martensitic stainless steel with good abrasion resistance and superior corrosion resistance to the 17% Cr to 1% C range (type 440C). The grade can also be ESR remelted to improve its inclusional cleanliness and corrosion resistance.

STAINLESS FRÜCHTL has a range of sizes in stock to suit your processing requirements. This product can also be custom made or cut into slugs by our service centres.

Main applications

Due to its good corrosion resistance and high hardness in the treated state (>56HRC), the grade is used in the manufacture of medical instruments (screwdrivers, drills, cutting guides, etc.), in bearings, in the chemical and food industries and in the cutlery industry.

Metallurgy

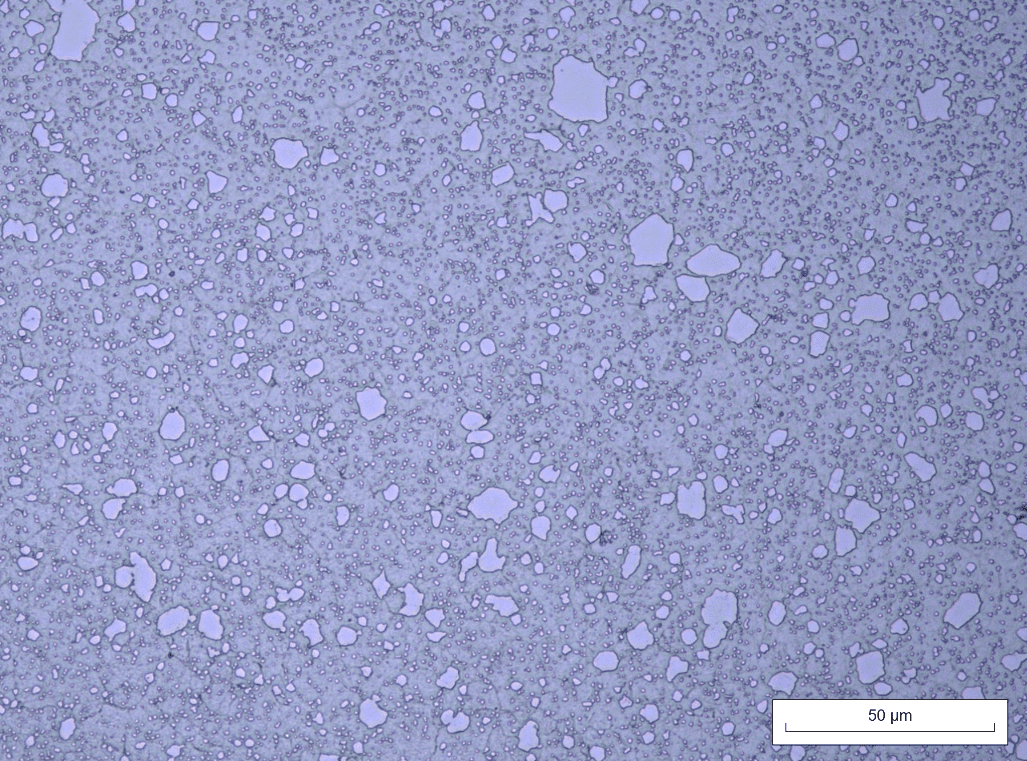

The melting processes combined with the transformation processes make it possible to obtain a homogeneous microstructure with a homogeneous distribution of carbides. In the processed state, the microstructure consists of martensite and undissolved carbides (see photo below):

Machinability

Typical heat treatments

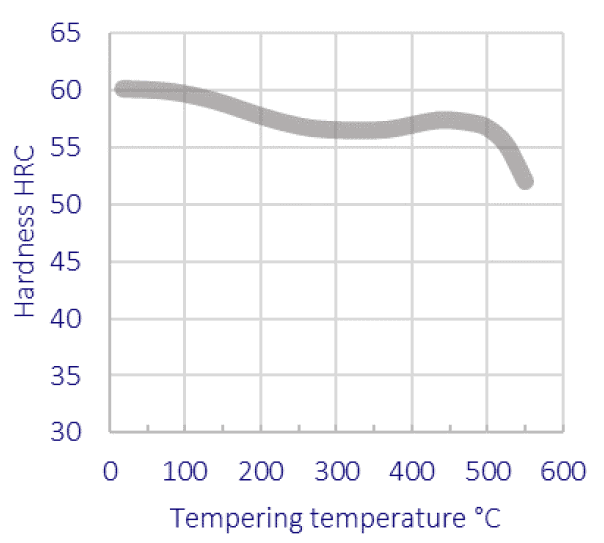

Heating: 1000-1050°C / oil then tempering according to the curve below:

Corrosion resistance

The corrosion resistance is strongly degraded in the annealed state or after welding, which is not recommended.

Standard Sizes

Rolled or forged round bars, annealed condition (Condition A) up to approx. 300mm, forged blocks – Surface ground or peeled according to diameters

Other formats: please consult us