17-4PH / 1.4542 – X5CrNiCuNb16-4 – AISI / SAE 630 / ASTM F 899 / ASTM A564

Description

Alloy 1.4542 or 17-4PH is a structurally hardened martensitic stainless steel that combines a hardness of around 43 HRC with very good corrosion resistance. This grade has a hardening peak at 480°C, making it easy to carry out ageing after machining on a condition initially in solution (condition A). The grade is also available pre-treated and/or as an aerospace-grade remelted version.

Stainless has several sources in stock, as well as different product formats and conditions, to meet your processing requirements. This product can also be made to measure or cut into blanks by our service centres.

Main applications

Thanks to its good resistance to corrosion, its good hardness in the treated state (43HRC) and its resilience, the grade is used in particular in the manufacture of instruments for the medical sector, general mechanics, the food industry and the automotive industry.

Metallurgy

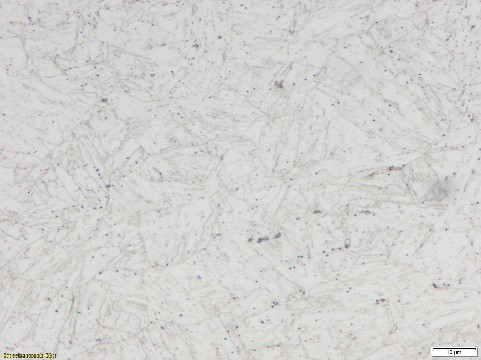

The manufacturing processes combined with the transformation processes produce a homogeneous microstructure. In the treated state, the microstructure consists of martensite and nanometric intermetallic precipitates (Ni3Cu) that germinate during ageing.

Machinability

Forgeability

The grade can be hot forged in the 950/1200°C temperature range. Resolving will be necessary to achieve maximum hardness.

Weldability

The grade can be welded using most processes. Welding should preferably be carried out before ageing to avoid embrittling the heat-affected zone.

Typical heat treatments

| For a target hardness ≥ 40HRC |

| – Heating 1030/1050°C – Oil quench – H900 ageing (480°C /2h) |

Volume shrinkage of up to approximately 0.07% is to be expected during ageing.

Corrosion resistance

17-4ph is highly resistant to corrosion and is one of the best martensitic stainless steels. The microstructure contains little or no chromium carbides, making it highly insensitive to intergranular corrosion.

Standard Sizes

Round or flat bars, annealed (Condition A or AT) or pre-treated – Surface hardened or ground depending on diameter

Flat bars made to measure in the annealed condition (consult us)

Other formats: forged blocks, sheet, strip, powder.

FIND OUT MORE ABOUT : 1.4542

Don't hesitate to contact us for more information.-

What is 1.4542?

Grade 1.4542 is a martensitic alloy hardened by precipitation during ageing, which follows annealing at high temperature followed by quenching. Its hardness can reach 43 HRC, during the hardening peak at 480°C. The alloy contains chromium, nickel, copper and molybdenum, giving it excellent corrosion resistance and high mechanical strength.

-

Why 1.4542 in the medical sector?

1.4542 has properties such as corrosion resistance, which are also important in the medical sector, where the alloy is used for instrumentation and medical devices in sectors such as cardiology, neurology, ophthalmics and mobility aids. Our customers in these sectors offer real expertise through their development and their wide range.

The grade offers an ideal, cost-effective compromise between corrosion resistance and mechanical strength for surgical instrumentation.

-

Can 1.4542 be properly machined?

Yes, its very good machinability is interesting for sectors such as industry, where many parts are milled and turned. The grade is suitable for hot forging at between 900 and 1,250°C and for welding, which can be carried out using most processes, although this must be done before ageing.

-

What do the 17-4PH standards mean?

Many of these standards are for surgical instrumentation. ASTM F899 is a standard specification for wrought stainless steels for surgical instruments. NF S 94-090 is an AFNOR standard for medical and surgical materials made of martensitic, precipitation-hardened, austenitic and austeno-ferritic stainless steels, and ISO 7153-1 also covers these products.

The latter also includes alloys used in general surgery, orthopaedic surgery and oral medicine. ASTM A564 is a specification that does not directly concern the medical sector, but bars and shapes such as rounds and flats in hot-hardening and/or cold-finishing stainless steel. These standards partly define the grade and its uses.

-

What reports and formats does STAINLESS offer?

1.4542 is an important grade for STAINLESS FRÜCHTL, the German subsidiary of the STAINLESS group, thanks to its interesting properties such as hardness and corrosion resistance, for a wide range of sectors, from medical instrumentation to aerospace and industry. The grade is offered either in the annealed condition with a maximum hardness of 360 HBW or in several thermal condition A conditions: H900, P800/H1050, P1070/H1025.

It is available in a variety of formats: round or flat bars, forged blocks and sheet metal. This product can be made to measure or cut into blanks by our service centres.